Customized planning software

The Capaul Planner is a simple planning and control tool that optimizes the operation of Capaul’s precision machinery and its workforce.

Customer

Capaul

Industry

Precision mechanics

Services

UI/UX design, development, support, project management

Technologies

ASP.NET Core, Azure SQL Server, Azure Pipelines, Docker, React

About Capaul

Capaul is a leading manufacturing company specializing in precision engineering for the aerospace, rail, energy and medical industries. The company has been established for over 150 years and prides itself on the extensive machinery and operations team that works to deliver products quickly and to the highest quality. Precision is at the heart of everything they do. Working in such a fast-paced environment means there is a need to manage resources as efficiently as possible.

The Production Manager is responsible for:

- Production and staff planning

- Provision and inventory of required materials

- Coordinating delivery dates

- Operational planning

- Production execution and performance monitoring

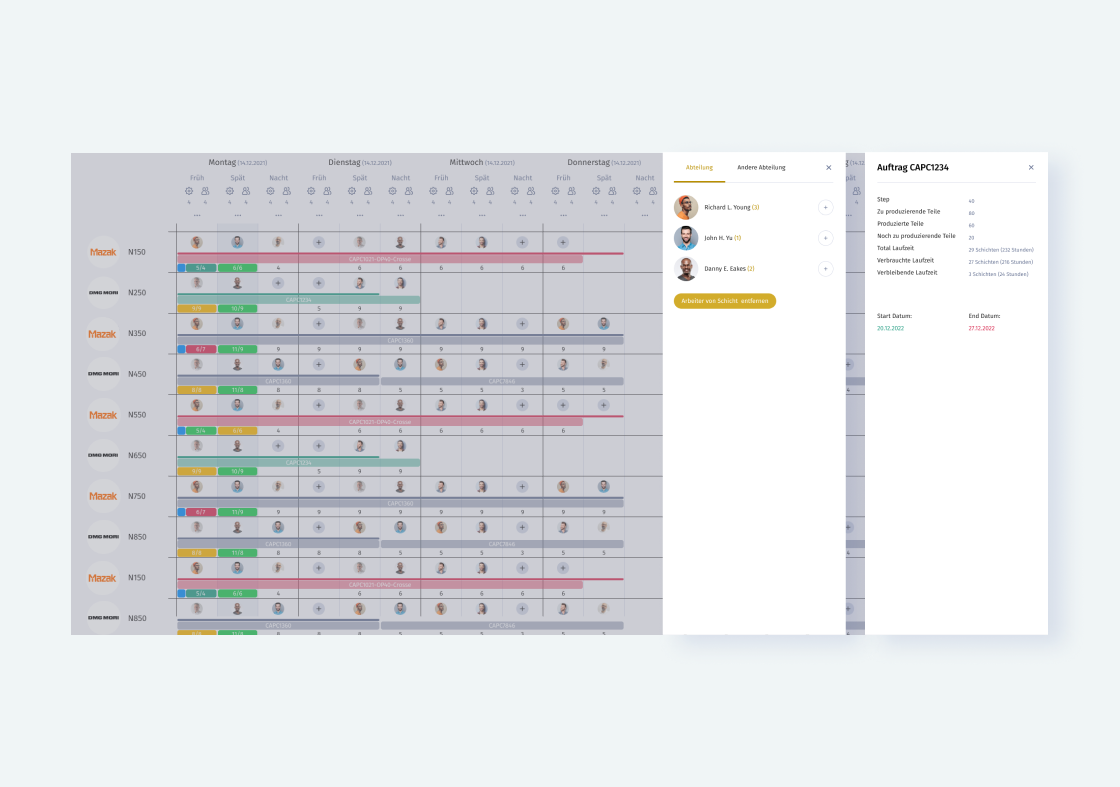

The Production Manager is also responsible for allocating a machine for each individual job, as well as the member of staff who will be responsible for that task, the team members who are available and whether a member of staff is either under or over-worked. They also need to determine whether a specialized team member is required for the set-up of a machine.

For Capaul’s workflow not to be compromised, it is vital that the workforce is informed on all upcoming assignments.

A company-wide dashboard is required so that all staff have visibility of the workload and how it has been prioritized. Within this dashboard, the team can also give useful feedback to the Production Manager - for example, whether the given schedule is realistic or not.

The challenge

Planning your resources manually can be extremely time-consuming and often prone to error. A Production Manager will be wasting a lot of valuable time with these administrative tasks.

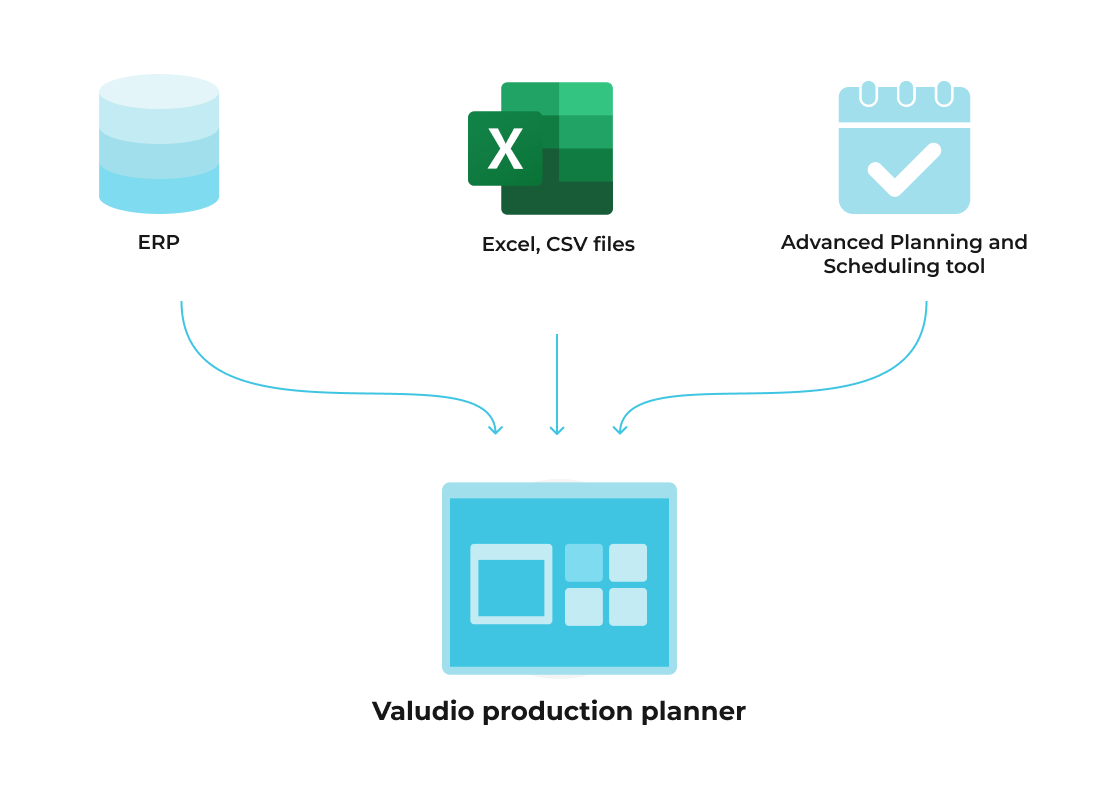

Capaul already uses two different systems to plan production: an ERP system (Enterprise Resource Planning system) to manage orders and an APS tool (Advanced Planning and Scheduling tool) to simulate the optimal scheduling of each order on the individual machines.

In order to schedule both team members and machinery, the information from both these systems must be entered manually into an Excel file. A progress report must also be manually updated in this file on a daily basis.

To remove a labor-intensive, error-prone process, an automated, digital solution is needed.

Solution requirements

For Capaul to perform at their very best, they need a platform that automatically integrates the information from the ERP and APS tools and considers the availabilities of the workforce. In addition, the platform must allow daily updates of the production progress on each machine, plus automatically calculate possible delays or progress in the expected schedule.

Implementation

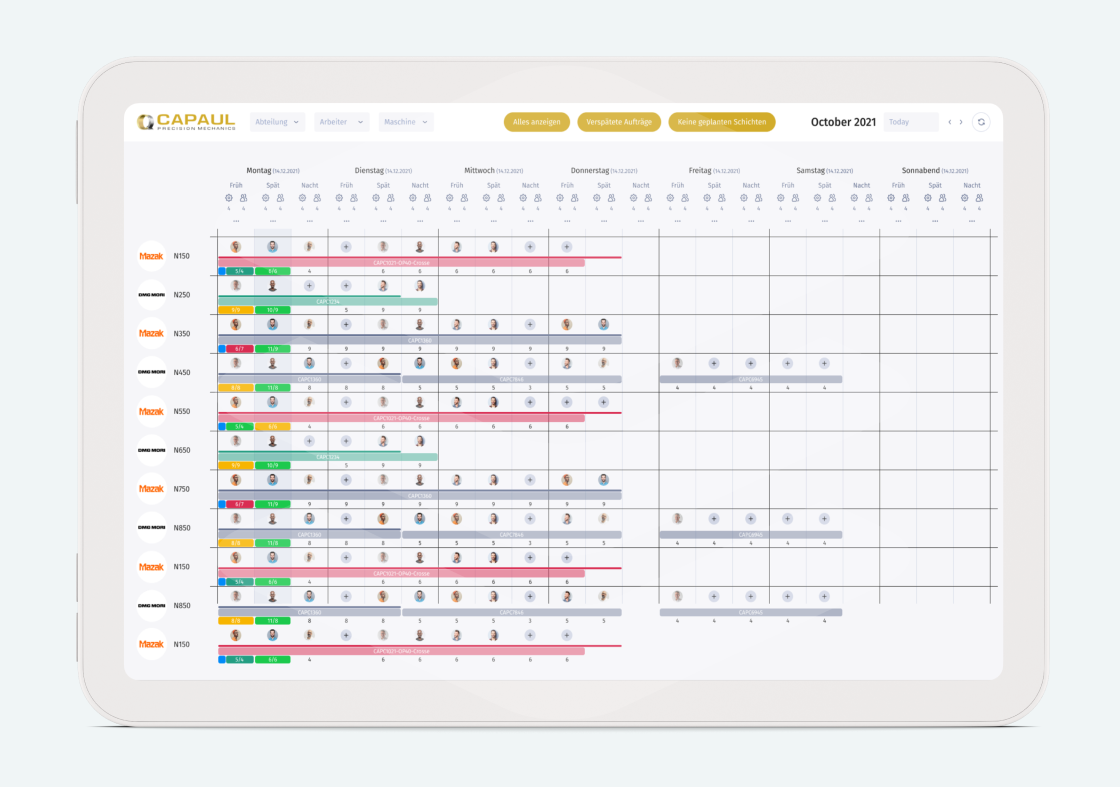

Together with Capaul, Valudio developed a planning tool that seamlessly and continuously integrates information from the ERP and APS systems. The Capaul Planner automatically assigns to a calendar view when orders need to be produced on a particular machine, it also calculates the expected production volumes of each shift. The Production Manager can assign resources per machine and per shift accordingly.

After each shift, the number of products produced will be updated, triggering a recalculation of the time needed to complete the job. Thanks to the user-friendly and simple design of the Capaul Planner, everyone in the company can now see at a glance who is responsible for each machine, as well as the status of each order and track delays.

The result

To maximize productivity and to help a business thrive, it is vital to streamline the administrative processes where possible. By doing this, it means the day-to-day focus can be spent doing the tasks that really matter.

The Capaul Planner allows just that.

By creating a digitalized organization platform for Capaul's workflows, the Production Manager can now better manage their time. After using the Capaul Planner for just a few months, it has been proven to be a worthwhile asset. The workforce now enjoys:

✓ smart shift planning thanks to a user-friendly interface.

✓ 8 hours of time saved per week in production planning and monitoring.

✓ increased productivity and reliability of delivery dates

✓ automated calculations instead of error-prone manual entries

✓ a planning tool that is up-to-date 24/7

✓ planning reliability for several weeks in advance

✓ improved communication and transparency around the current order situation and staff utilization

Tech Stack

- ASP.NET Core

- Azure SQL Server

- React